Work Order less completion is an alternate way of producing goods without going through the discrete job cycle. In this process you directly enter the assembly and quantity to be produced and onhand inventory will be updated immediately. Upon completing the work order less completion all components are back flushed and resources are charged to the schedule.

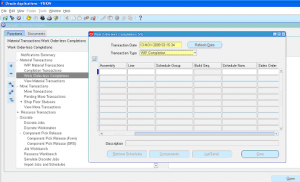

Navigate to Work In Process responsibility -> Material Transactions -> Work Order less completions

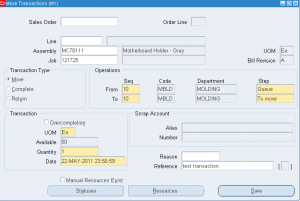

wip work order less completion

1 ) Enter the transaction date or modify the default date.

2 ) Chose the transaction type as ‘WIP Completion’.

3 ) Enter assembly item number.

4 ) Enter the production line.

5 ) Enter Schedule Group.

6 ) Enter Schedule number (equivalent of work order/discrete job number for reference).

7 ) Enter the completion subinventory and locator(if applicable).

8 ) Select the WIP accounting class/demand class and transaction reason code.

9 ) Click on Save to complete ‘work order less completion’ transaction.