Discrete Job Creation

Discrete Job or Work In Process (WIP) Job is a work order issued to shop floor to manufacture or assemble an item.

WIP Jobs can be created in 6 different ways

- Manually enter/create.

- Convert from a simulation.

- Planned order release from Supply Chain Planning / MRP.

- Planned order release from Advanced Supply Chain Planning.

- Auto create from a Configure to Order (CTO) Sales Orders.

- Using work order open interface

In this section you will learn how to create WIP jobs manually.

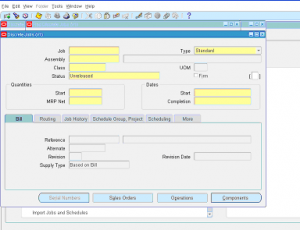

Navigate to Work In Process responsiblity -> Discrete -> Discrete Jobs.

1 ) Enter the WIP Job number manually or tab out to generate the Discrete WIP Job number automatically.

2 ) Select Discrete Job type.

3 ) Enter the assembly that needs to be manufactured.

4 ) Enter WIP Job class

5 ) WIP Job status – by default it will be in ‘created’ state, once you are ready to manufacture you can change the status to ‘Released’.

6 ) Enter the Start quantity i.e. total quantity that will be manufactured.

7 ) MRP net quantity – This is the quantity that MRP assumes available as supply. This should be less than or equal to start quantity (total quantity of discrete job).

8 ) Dates: Enter the start and completion dates. Completion date can be blank, it will be calculated based on lead time when wip job scheduled.

9 ) Navigate to ‘Bill’ tab – Select the specific item bom revision

10 )Navigate to ‘Routing’ tab – Select specific item routing revision, set the assembly completion subinventory & locator

11 )Navigate to ‘More’ tab to enter demand class, job description & overcompletion tolerance. Over completion tolerance let you produce more/less quantity than actual quantity planned.

12 ) Click on ‘Operations’ button to view the default operations from assembly routing. This information can be modified.

13 ) Click on ‘Components’ button to view the default components from assembly bom. This information can be modified.

14 ) Finally change the WIP job status to ‘Released’ to start the discrete job manufacturing.