Fusion Distributed Order Orchestration Overview

October 10, 2010 in Fusion Distributed Order Orchestration

Fusion Distributed Order Orchestration

Distributed Order Orchestration (DOO) is one of the new module that oracle consider as part of Fusion Applications suite. Fusion Applications is a new version Oracle ERP that is considered as migration path for Oracle Apps, JD Edwards, Siebel and other e-business applications oracle acquired over the last few years.

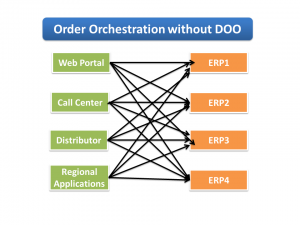

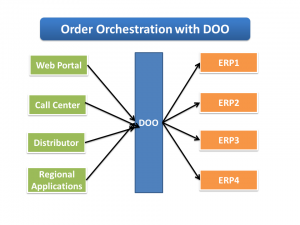

Often every business have multiple order entry systems to capture orders that goes through multiple ERP systems. Businesses spend considerable IT efforts to build complex interfaces. Oracle Distribution Order Orchestration provides consolidated order capture system that receives orders from multiple sources and routes it to multiple manufacturing plants/systems through flexible business rules.

Complex Order fulfillment without DOO:

Simplified Order fulfillment with DOO:

DOO features:

- Decomposition:

- Rules workbench that can decompose one sales order into multiple sales orders across different fulfillment (ERP/Manufacturing systems).

- Manage order changes

- Provides consolidated order status

- Orchestration:

- Business Process Management (BPM) Administration

- Managing order related tasks and execution (installation, notifications etc)

- Simulation order changes and cost implications.

- Integration:

- Global order Promising by out of the box integration with GOP module. GOP provides sourcing rules and promise dates

- Integration with oracle fulfillment modules

- AIA integration