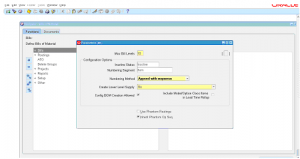

Bills Of Material parameters are setup for each inventory organization. It controls some basic behaviour of BOM module.

Navigate to BOM responsibility –> Setup –> Bills Of Material Parameters.

1 ) Max Bill Levels: This limits the number of levels BOM can be setup

2 ) Inactive status: To make any Item/BOM inactive we need select the appropriate status code that is used for inactive. These status codes are defined as setup and attached to Items.

3 ) Numbering Segment: Used when creating configuring items. Usually it is ITEM.

4 ) Numbering method: You can set automatic or user defined numbering method. Different values you can set are

Append Sequence

Replace with sequence

Replace with Order, Line number

User Defined

5 ) Create Lower Level Supply: Select YES or NO.

6 ) Config BOM Creation allowed: Check or uncheck. Usually check this in manufacturing orgs where the config BOM must exists to manufacture that assembly.

7 ) Inlcude Model/Option class items in lead time rollup: Check to roll up the lead times.

8 ) Check or uncheck ‘Use Phantom Routings

9 ) Check or uncheck Inherit phantom Operation sequence