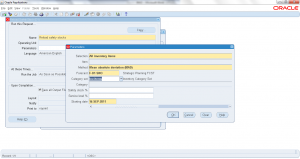

7.3 View Demand History

- Form Application: Inventory

- Form Name: INVDVFDH

- Form Path: /oracle/apps/r12/visr12/apps/apps_st/appl/inv/12.0.0/forms/US/INVDVFDH.fmx

Demand History is used in forecast generation. Demand History is summarized form of historical demand. Demand can be summarized in to days, weeks or any periods. Concurrent program ‘summarize demand history’ consolidates the demand history. Using ‘View Demand History’ form you can view the compiled demand history.

Navigation: Inventory responsibility -> Planning -> Demand History

- Enter the search criteria

- Category Set

- Category

- Items From

- Item To

- Item Description

- Click ‘FIND’

- Output shows the compiled demand history

- Item

- Description

- Unit of measure

- Compiled bucket type – Day, week, period

- Click on ‘History’ to see additional details

This is just view only screen and you can’t make any changes.